With a solid understanding of your Singer 301, you can master the intricate process of threading your sewing machine. This imperative skill not only enhances your sewing experience but also ensures your projects turn out flawlessly. In this guide, you will discover step-by-step instructions to help you confidently navigate the complex threading paths, avoiding pitfalls that can lead to frustrating sewing sessions. Learn to troubleshoot common issues and unlock the full potential of your machine for stunning results.

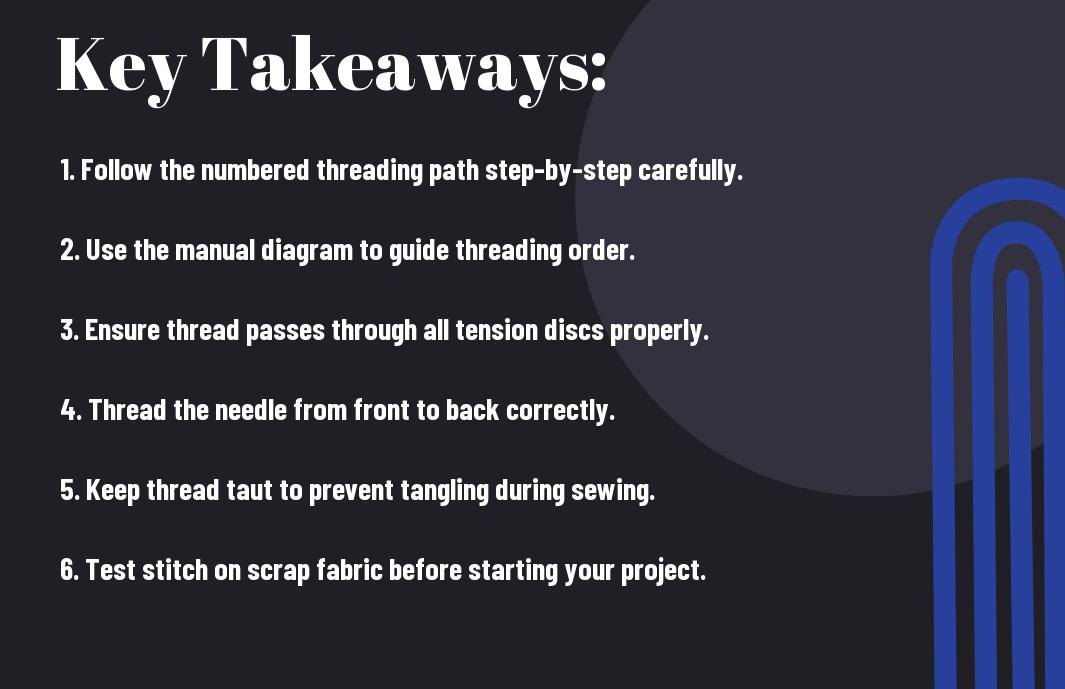

Key Takeaways:

- Familiarize yourself with the machine’s threading diagrams, as they provide a visual guide to correct thread paths.

- Always thread the machine in the correct order, starting from the spool and following the designated pathway to avoid jams.

- Regularly practice threading to build confidence and efficiency, ensuring accurate and consistent results in your sewing projects.

The Anatomy of the Singer 301: Essential Components Unveiled

The Singer 301 is a well-crafted sewing machine boasting several important components that make it user-friendly and efficient. Understanding these components is key to mastering its threading process. With a blend of mechanical engineering and user-friendly design, the 301 enhances your sewing experience while minimizing threading errors and improving overall productivity.

Key Features That Influence Threading

Several features of the Singer 301 play a pivotal role in how you thread your machine effectively. These elements enhance stability and precision in your sewing.

- Thread Path Guide: Visual directions that facilitate accurate threading.

- Tension Discs: These control the thread tension during stitching.

- Needle Position: The adjustable needle position affects stitch quality.

- Spool Pin: Holds the thread spool securely in place.

- Take-up Lever: Ensures that the thread feeds properly during sewing.

Knowing these features will simplify your threading process and enhance your overall sewing experience.

Understanding the Tension Mechanism

The tension mechanism of your Singer 301 is pivotal in ensuring that your stitches are not too loose or too tight. It involves a series of tension discs that guide the thread through the machine. This mechanism maintains a consistent tension throughout the sewing process, allowing for even and balanced stitches. Typically, if the tension is too high, you may experience thread breakage, while too low tension can result in loopy stitches. Regularly checking the tension setting based on the fabric type and thread weight is important for achieving optimal results in your sewing projects.

Easing into the Threading Process: A Step-by-Step Guide

| Preparing Your Machine for Success |

Check your Singer 301’s settings, ensuring it’s powered off before you start. Remove any old thread and clean the machine, especially around the tension discs and feed dogs. Ensure your presser foot is up, allowing the thread to flow freely through the tension mechanism. These small steps significantly impact your machine’s performance and thread consistency. |

| The Thread Path: Visualizing the Route |

Familiarize yourself with the diagram located on your machine. This visual guide details the exact path the thread follows from the spool to the needle. Following this established route ensures proper tension and stitch formation, ultimately contributing to the quality of your sewing projects. |

The Thread Path: Visualizing the Route

Understanding the path the thread takes through your Singer 301 is crucial for successful sewing. The thread must navigate through various components, including the tension discs, take-up lever, and needle. Each part plays a vital role in controlling the thread’s flow and tension. By following the threading diagram closely, you can avoid common pitfalls like thread jams or uneven stitching. Ensure that the thread passes smoothly without any tangling or snagging, which can disrupt your work.

Common Pitfalls in Threading the Singer 301: What to Avoid

This machine, while user-friendly, can lead to complications if specific errors aren’t avoided during threading. Failing to correctly follow the threading path can create a series of issues, such as thread breakage and inconsistent stitch quality. Inadequate tension adjustments, not using the correct thread type, or overlooking the use of the threading guide all contribute to the frustrations that can arise. Steer clear of these common pitfalls, and your sewing experience will be all the more enjoyable.

Missteps That Mess with Tension

Tension adjustments are a delicate balancing act. Over-tightening the thread can lead to breakage, while too loose a tension can cause thread loops on the underside of your fabric. Often, mistakes happen when you skip checking the thread tension settings during or after threading, resulting in uneven stitches. Prioritize this adjustment to avoid those frustrating moments that can derail your sewing project.

Why Incorrect Threading Leads to Frustration

Incorrect threading creates a chain reaction of sewing disasters—from thread breaking to fabric puckering. When the thread is not properly aligned through guides, it fails to have the correct tension needed for smooth stitching. This can disrupt your workflow, waste precious fabric, and lead to a cycle of re-threading and troubleshooting. Investing your time in understanding the proper threading process prevents these headaches and enhances your overall sewing experience.

Leveraging Troubleshooting Techniques for Smooth Operation

Even experienced sewers encounter threading hiccups with the Singer 301. Employing troubleshooting techniques can help you identify and address threading issues efficiently. If the thread jams or breaks, knowing where to look for faults in your setup will save you time and frustration. Keeping tools and solutions handy allows for immediate rectification, ensuring your sewing remains uninterrupted.

Diagnosing Common Threading Issues

When thread problems arise, the first step is to diagnose the common issues affecting the Singer 301. Check for improper thread tension, as this can cause skipping stitches or uneven seams. Ensure that you have correctly threaded the machine, as misalignment can lead to tangled threads. Lastly, verify that you are using the appropriate thread type for your fabric, as using the wrong material can compromise performance.

Quick Fixes and Maintenance Tips

To ensure smooth operation, implement quick fixes and maintenance practices regularly. Keep the machine clean by removing lint and dust from the bobbin area and upper threading paths. Use quality threads and needles, as worn-out or inferior materials may contribute to threading problems. Performing routine checks on the tension settings and components will also prolong the life of your machine. This can significantly reduce potential threading issues.

- Remove lint and dust from the machine.

- Use quality threads and needles.

- Perform routine checks on tension settings.

- This helps maintain consistent performance.

Maintaining your Singer 301 is key to a smoother sewing experience. Regularly inspect your machine’s parts, including the presser foot and feed dogs, for wear and tear. Lubricating the machine according to manufacturer instructions ensures that all moving parts function optimally. Avoid overloading your machine or sewing excessively on thick fabrics without adjustments, as this can lead to unnecessary strain. This attention to detail will keep your machine running smoothly for years to come.

- Inspect presser foot and feed dogs frequently.

- Lubricate the machine as per manufacturer instructions.

- Avoid overloading your machine or sewing on thick fabrics.

- This will maintain your machine’s efficiency.

Unleashing Creative Potential: Mastering Your Singer 301’s Threading

Threading your Singer 301 isn’t just a mechanical task; it’s a gateway to unlocking your creative sewing abilities. Mastering this skill allows you to fine-tune your fabric handling and adapt your techniques, enabling you to sew with precision and flair. Whether you’re a beginner or a seasoned expert, understanding the nuances of threading will enhance your projects and open new horizons of creativity.

How Threading Influences Fabric Handling

Threading plays a significant role in how fabric behaves under your Singer 301. Inadequate tension settings can lead to puckering or stretching, while proper threading allows for smooth, even seams. You’ll notice the difference in the way fabric feeds through the machine, affecting everything from stitch quality to ease of handling. By honing your threading skills, you gain control over the outcomes of your sewing projects.

Expanding Your Sewing Techniques with Advanced Threading

Advanced threading techniques can elevate your sewing to a new level. By mastering double-needle stitching or utilizing specialty threads, you can create unique textures and styles. These methods give you the flexibility to explore different types of fabrics—lavish silks, stretchy knits, or delicate sheers—effectively broadening your project possibilities.

- Experiment with different types of thread.

- Use a double needle for unique stitching styles.

- Adjust tension settings for various fabric weights.

- Learn to create decorative stitches.

| Technique | Description |

|---|---|

| Double Needle | Adds parallel lines of stitching, perfect for hems. |

| Specialty Threads | Use metallic or clear thread to achieve unique effects. |

| Tension Adjustments | Adjust tension for different fabric weights ensuring smooth stitching. |

| Decorative Stitches | Create intricate designs that enhance visual appeal. |

Engaging with advanced threading techniques not only enhances your skillset but also empowers your creative vision. Utilizing a double needle can transform straight lines into dynamic patterns, while experimenting with specialty threads opens up a realm of textures. Understanding how to adjust your tension for various fabric types ensures your projects turn out flawlessly, allowing you to enjoy each step of the sewing journey.

- Master tension for flawless stitching.

- Explore decorative options with specialty threads.

- Combine techniques to develop personal style.

- Push boundaries of fabric types you use.

| Skill | Benefit |

|---|---|

| Double Needle Expertise | Enriches design without complicating sewing processes. |

| Mastery of Specialty Threads | Enhances texture and aesthetics of your projects. |

| Sophisticated Tension Control | Ensures consistency regardless of fabric weight. |

| Creative Stitch Variations | Allows for personalized and signature sewing styles. |

Final Words

The process of navigating the labyrinth of Singer 301 threading may seem challenging at first, but with practice, you can master it effectively. By familiarizing yourself with the threading path and following each step carefully, you can ensure that your machine operates smoothly. Don’t hesitate to consult your manual or seek tutorials if you encounter difficulties, as these resources are invaluable. With perseverance and attention to detail, you will gain confidence in your threading skills, making your sewing experience more enjoyable and efficient.

FAQ

Q: What are the initial steps to prepare my Singer 301 for threading the machine?

A: Before you begin threading your Singer 301, ensure that the machine is turned off and unplugged for safety. Locate your spool of thread and place it on the spool pin. Next, raise the presser foot to release the tension discs. This step is crucial as it allows the thread to move freely through the machine. Lastly, it’s a good idea to consult your manual for any specific threading instructions unique to your model.

Q: How do I properly thread the Singer 301 to avoid common issues?

A: Start by following the threading path indicated on the machine. Pull the thread from the spool and follow the designated guides—this usually involves going through a slot on the top of the machine, around a tension dial, and down to the needle area. If your machine provides a diagram, use it as a visual reference. After threading, make sure to check that the thread is seated correctly in the tension discs and that it passes through the needle from front to back. This will help prevent issues like thread breakage or improper stitching.

Q: What should I do if the thread keeps jamming during the sewing process?

A: If you encounter jamming, first stop sewing and check the upper threading. Detach and re-thread the machine, ensuring that the thread is not tangled and is seated properly in the tension discs. Also, check the bobbin area for any entangled threads or debris that might cause obstruction. Make sure the bobbin is correctly wound and inserted in the machine. If issues persist, consider cleaning the machine to clear any lint or dust that could be affecting the threading and overall performance.