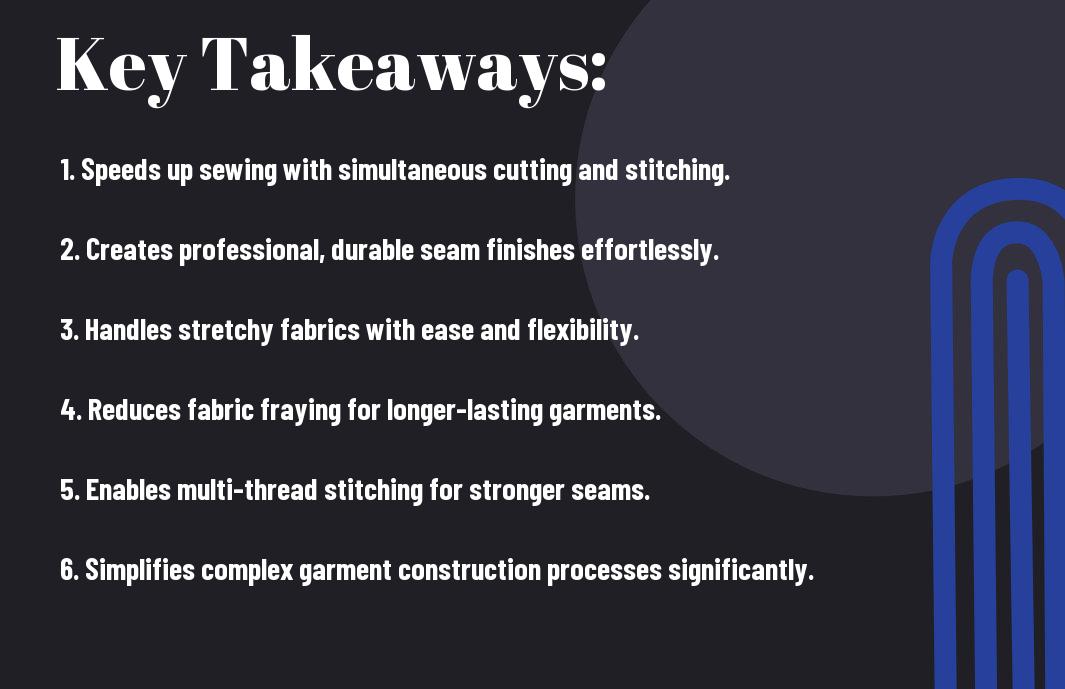

It’s time to elevate your sewing game, and a serger sewing machine might be just what you need. This powerful tool can save you time and deliver professional-quality finishes to your garments, allowing you to focus on creativity rather than tedious detailing. With its ability to trim, stitch, and overcast simultaneously, you can achieve clean, durable seams that stand the test of time. Embracing this technology not only enhances your skills but also transforms your overall sewing experience, simplifying garment construction like never before.

From Frustration to Innovation: The Limitations of Conventional Sewing

Conventional sewing methods often present limitations that can hinder your creativity and slow down production. Whether struggling with finishing seams, achieving consistent tension or dealing with fabric shifting, these challenges can lead to time-consuming alterations and unsatisfactory results. The tedious nature of these tasks frequently leads to *frustration*, which is counterproductive to the design process. As a designer, your focus should be on innovation and ensuring high-quality craftsmanship, not getting bogged down by the shortcomings of traditional sewing machines.

Common Challenges Faced by Tailors and Designers

Tailors and designers frequently encounter obstacles such as *inconsistent tension*, fraying edges, and difficulty working with stretchy or slippery fabrics. These issues can result in *time-consuming revisions* and affect the overall quality of your garments. Moreover, as projects scale, managing multiple layers and materials can become overwhelming, leading to wasted fabrics and resources. The quest for perfection in sewing can sometimes feel like an uphill battle.

The Need for Enhanced Efficiency in Garment Construction

Efficiency in garment construction is vital for staying competitive in the fast-paced fashion industry. With consumer demand soaring and trends changing rapidly, you need to streamline your processes to keep up. Traditional sewing techniques often lack the speed and precision necessary for large-scale production, which makes investing in innovative solutions important. By implementing tools that boost efficiency, you enable yourself to focus more on design and less on troubleshooting.

Enhancing efficiency in garment construction means more than just speeding up the sewing process; it also involves optimizing the entire workflow. For instance, integrating a serger sewing machine can seamlessly finish seams while allowing you to sew intricate details that elevate your designs. By reducing the hours spent on finishing touches, you can significantly increase your output and devote more time to creative exploration. Ultimately, this shift leads to enhanced productivity, enabling you to respond swiftly to market demands and bring your vision to life without compromise.

Unlocking the Efficiency: How Serger Machines Work

Serger machines employ a distinctive sewing technique that combines multiple threads to create strong seams while finishing raw edges simultaneously. With the ability to perform overlock stitching, these machines trim and enclose fabric edges, reducing fraying and enhancing durability. This streamlined process significantly speeds up garment construction, allowing you to produce professional-quality results in a fraction of the time it would take with a conventional sewing machine.

The Mechanics Behind a Serger Sewing Machine

With two or more needles and multiple thread paths, serger machines create a unique stitch that binds, trims, and finishes seams in one step. The use of a built-in knife allows for precise fabric cutting while sewing, which not only streamlines the process but also enhances the overall finish of your garment. This advanced functionality sets sergers apart from traditional sewing machines, making them indispensable for fast and efficient garment creation.

Key Features That Differentiate a Serger from Regular Sewing Machines

Several standout features define serger machines and set them apart from conventional sewing machines. These specialized characteristics enhance your sewing experience and efficiency:

- Overlock Stitching: Creates woven edges and prevents fraying.

- Multi-thread Capability: Utilizes two to five threads for versatility.

- Built-in Cutter: Trims fabric edges while sewing, ensuring neat finishes.

- Fast Sewing Speed: Can sew at speeds up to 1,500 stitches per minute.

- Adjustable Presser Foot Pressure: Accommodates various fabric thicknesses.

After understanding these features, you’ll appreciate why a serger is an imperative tool for sewing enthusiasts and professionals alike.

Consider how these features elevate your sewing projects. The overlock stitching not only adds a professional touch but also increases the durability of your seams. The multi-thread capability provides versatility unknown to standard machines, allowing you to tackle various fabric types with ease. A built-in cutter streamlines your process by minimizing the number of steps, whereas the impressive fast sewing speed means you can complete projects in a fraction of the time. The adjustable presser foot pressure allows you to manipulate different fabric weights efficiently. After exploring these advanced features, the choice to incorporate a serger into your sewing toolbox is clear.

Seam Types and Techniques: The Versatility of Serger Sewing

A serger sewing machine opens up a world of seam types and techniques, allowing you to expand your garment construction skills. With its ability to create a variety of stitches such as overlock, flatlock, and rolled hems, it provides versatility that regular sewing machines lack. Sergers also offer the added benefit of trimming excess fabric while sewing, resulting in polished edges. The efficiency and adaptability of a serger can enhance your creativity, significantly reducing the time spent on each project. Assume that incorporating a serger into your toolkit will elevate your sewing game.

| Seam Type | Function |

| Overlock | Prevents fraying and creates a clean finish. |

| Flatlock | Creates flat seams for a comfortable, finished look. |

| Rolled Hem | Gives a delicate finish on lightweight fabrics. |

| Coverstitch | Provides a professional, ready-to-wear finish for hems. |

| Chain Stitch | Allows for stretch and flexibility in garments. |

Exploring the Unique Stitching Capabilities of Sergers

Sergers can create several distinct stitches that are tailored to various fabric types and garment requirements. For instance, the ability to make a flatlock stitch allows you to design garments with a smooth surface, making them comfortable against the skin. Likewise, rolled hems provide an elegant finish, perfect for silk or lightweight materials. Each stitch produced by a serger serves a specific purpose, empowering you with the capability to handle challenging textile projects effortlessly.

Innovations in Hemming, Seaming, and Finishing

The latest serger models boast advanced features that redefine hemming, seaming, and finishing techniques, making them more accessible and efficient for you. These machines enable multiple thread options, offering the ability to select the ideal thread type for your projects. Additionally, technology has paved the way for more intuitive controls, ensuring consistent results every time. With built-in tension adjustments and color-coded threading guides, you can quickly master complex techniques without frustration.

Innovations in the serger design streamline the sewing process significantly. Features like automatic tension adjustments help maintain the perfect stitch no matter the fabric thickness, while advanced differential feed settings allow you to work seamlessly with stretch and knit fabrics. The time savings from these improvements allow you to focus on creativity rather than troubleshooting. Plus, enhanced user interfaces and tutorial settings in new models make learning these finishing techniques simpler than ever. This ensures that your garment sewing is not just about utility but also about achieving professional-quality results with ease.

Financially Speaking: The Economic Benefits of Using a Serger

Investing in a serger sewing machine can yield substantial financial advantages for both hobbyists and professional designers. With its ability to streamline garment construction processes, a serger can help you cut down on costs and maximize profits. Whether you’re working on personal projects or running a small business, the economic benefits of using a serger are hard to ignore, making it a worthy addition to your toolkit.

Cost Savings Through Reduced Fabric Waste

Using a serger helps minimize fabric waste by employing precision cutting techniques, which often leads to a reduction in leftover materials. With its specialized blades and overlock feature, you can achieve neat and clean edges, maximizing the fabric you purchase. This not only saves you money on materials but also contributes to a more sustainable sewing practice, allowing you to make the most of every yard of fabric.

Time Efficiency Leading to Increased Production

By speeding up the sewing process, a serger allows you to complete multiple projects in a fraction of the time it would take with a conventional sewing machine. This time efficiency translates directly into increased production capacity, enabling you to take on more work, fulfill orders faster, and meet tight deadlines. As you become more skilled with a serger, you’ll notice a remarkable boost in your overall output.

For instance, when you use a serger, you can sew seams and finish edges simultaneously, reducing the number of steps involved in garment creation. This dual function not only saves time but also enhances your workflow. Numerous home-based business owners report being able to double their output by incorporating a serger into their production process. Imagine how much more you could create or sell when you can cut your production time in half—it’s a game changer for your creative business.

Empowering Creativity: The Artistry of Serger Techniques

The serger sewing machine not only simplifies garment construction but also enhances your creative expression. By experimenting with various stitch types and techniques, you can transform your projects into unique pieces of art. From intricate rolled hems to stylish flatlock seams, the versatility of serging allows you to explore new design possibilities while achieving professional-looking results. This empowerment fuels your creativity, turning routine sewing projects into an opportunity for innovation and personal flair.

Creative Stitching Ideas to Elevate Garment Design

Incorporating serger techniques into your garment design opens up a plethora of creative stitching ideas. You can easily add texture with ruffles, fringes, or decorative threads, creating visual interest that captures attention. Layering different stitches can also allow for contrasting colors and patterns, celebrating the uniqueness of your design while maintaining durability. With the power of a serger, your garments can reflect your personal style, making every piece truly one-of-a-kind.

Case Examples of Designers Who Embrace Serger Technology

Many innovative designers are fully utilizing the capabilities of serger technology to enhance their collections. For instance, renowned fashion label Stella McCartney often integrates clean serged edges for a modern finish in her sustainable pieces. Additionally, indie designers like Tilly and the Buttons incorporate serging to streamline their patterns, allowing for the production of stylish, ready-to-wear items while maintaining high-quality aesthetics. These examples illustrate how serging is not just a tool but an imperative part of the contemporary designer’s toolkit.

You’ll find that major players in the fashion industry have begun to embrace sergers as imperative tools for efficiency and creativity. For instance, Stella McCartney has mastered the art of using serged hems to create polished, eco-friendly garments without compromising on style. Likewise, indie designers like Tilly and the Buttons leverage serger technology to create patterns that resonate with DIY enthusiasts, showcasing their versatility and appeal. These case studies convey that embracing a serger can lead to innovative designs that attract attention in both retail and home-sewing markets alike.

To wrap up

Hence, investing in a serger sewing machine can significantly elevate your garment construction process, enabling you to achieve professional-quality finishes with ease. The ability to sew, trim, and overcast edges simultaneously allows you to save time while enhancing the durability of your projects. As you explore the creative possibilities of serging, you’ll find it empowers you to experiment with fabrics and techniques like never before, ultimately revolutionizing your sewing experience and turning your ideas into beautifully finished garments with confidence.

FAQ

Q: What is a serger sewing machine and how does it differ from a regular sewing machine?

A: A serger sewing machine, also known as an overlock machine, is designed specifically for seaming, edging, and finishing fabric edges in a way that prevents fraying. Unlike a regular sewing machine, which typically uses a single needle to create stitches, a serger can use multiple threads and specialized needles for a variety of stitch types. This allows for faster assembly, cleaner edges, and professional-looking hems, making it an important tool for garment construction.

Q: What advantages does a serger provide for garment construction compared to traditional methods?

A: The advantages of using a serger in garment construction are manifold. First, it can sew and finish seams simultaneously, saving you valuable time in the sewing process. Additionally, sergers create stretchable seams that are perfect for knit fabrics, helping to maintain the integrity of the garment through wear and wash cycles. The ability to trim excess fabric while stitching also results in a cleaner finish, enhancing the overall appearance of the garment without the need for additional steps.

Q: Can beginners effectively use a serger sewing machine for garment construction?

A: Yes, beginners can definitely utilize a serger sewing machine for garment construction, though it may require some initial learning. Many modern sergers come with user-friendly features, including color-coded threading guides and adjustable settings for various fabric types. With a bit of practice, new users can quickly develop their skills and begin to appreciate the efficiency and quality that a serger brings to their projects. Numerous online tutorials and sewing classes are also available to further assist beginners in mastering this valuable tool.